工程师用钕(Nd)离子掺杂氧化铝(Al2O3)晶体,开发出能够发射超短脉冲高功率脉冲的新型激光材料。他们的材料加工方法产生了Nd-Al2O3激光增益介质,其抗热冲击性能比领先的固态激光增益材料高24倍。

Nd and Al2O3 are two of the most widely used components in today’s solid-state laser materials. However, alumina crystals typically host small ions like titanium or chromium. Neodymium ions are too big — they are normally hosted inside a yttrium aluminum garnet (YAG) crystal.

Nd和Al2O3是当今固态激光材料中使用最广泛的两种元件。 然而,氧化铝晶体通常容纳小的离子,如钛或铬。 钕离子太大,它们通常位于钇铝石榴石(YAG)晶体内。

To address this issue, the team from the University of California, San Diego tailored the crystallite size to other important length scales, i.e., the wavelength of light and interatomic dopant distances, which minimized optical losses and allowed successful Nd doping.

The new process involves rapidly heating a pressurized mixture of Al2O3 and Nd powders at a rate of 300 °C per minute until the mixture reaches 1260 °C. This is hot enough to dissolve a high concentration of Nd into the Al2O3 lattice. The solid solution is held at that temperature for five minutes and then rapidly cooled, also at a rate of 300 °C per minute.

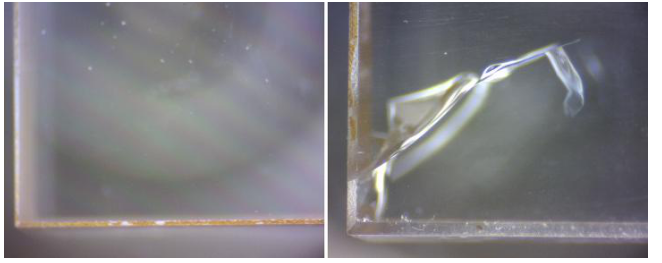

The team characterized the atomic structure of the Nd-Al2O3 crystals using x-ray diffraction and electron microscopy. To demonstrate lasing capability, researchers optically pumped the crystals with IR light (806 nm). The material emitted amplified light (gain) at a lower frequency IR light at 1064 nm.

In tests, researchers showed that Nd-Al2O3 has 24× higher thermal shock resistance than Nd-YAG, one of the leading solid-state laser gain materials.

“This means we can pump this material with more energy before it cracks, which is why we can use it to make a more powerful laser,” said professor Javier Garay.

Traditionally, alumina is doped by melting it with another material and then cooling the mixture slowly so that it crystallizes.

传统上,氧化铝通过用另一种材料熔化而掺杂,然后缓慢冷却混合物使其结晶。

“However, this process is too slow to work with neodymium ions as the dopant — they would essentially get kicked out of the alumina host as it crystallizes,” said researcher Elias Penilla.

The team speeded up the heating and cooling steps enough to prevent neodymium ions from escaping. The Nd-Al2O3 hybrid was made by rapidly heating and cooling the two solids together.

“Until now, it has been impossible to dope sufficient amounts of neodymium into an alumina matrix," Garay said. "We figured out a way to create a neodymium-alumina laser material that combines the best of both worlds: high power density, ultrashort pulses, and superior thermal shock resistance.”

The team is working on building a laser with their new material.

“That will take more engineering work," Garay said. "Our experiments show that the material will work as a laser and the fundamental physics is all there.”

“这将需要更多的工程工作,”Garay说。“我们的实验表明,这种材料可以用作激光,基础物理学就摆在那。”

The successful demonstration of gain and high bandwidth in a medium with superior Rs could lead to the development of lasers with previously unobtainable high-peak powers, short pulses, tunability, and high-duty cycles.

在具有优越Rs的介质中成功演示增益和高带宽可能会推动激光器的发展到具有先前无法达到的高峰值功率、短脉冲、可调谐性和高占空比。

转载请注明出处。

相关文章

相关文章

热门资讯

热门资讯

精彩导读

精彩导读

关注我们

关注我们