Laser Welding Technology for Vapor Chamber (VC) Heat Dissipation Component Manufacturing

source:Precision Welding Business Gro

keywords:

Time:2026-01-22

Source: Precision Welding Business Group of Han’s Laser

13th Jan 2026

Technical Background

In recent years, with the explosive growth in the demand for power density of electronic devices and components in the fields of artificial intelligence (AI), new energy vehicles, 3C consumer electronics and 5G communications, institutional forecasts indicate that the compound annual growth rate (CAGR) of the output value of the heat dissipation component industry will reach approximately 10%-15% from 2025 to 2035. By 2035, the global market size of heat dissipation components is expected to hit 300-400 billion US dollars, with China's market share likely to exceed 30%, making it the world's largest production and consumption market for heat dissipation components. Heat sinks have also evolved from auxiliary components into key core components that determine the performance, reliability and service life of equipment.

01 Artificial Intelligence (AI) / Data Centers

The pursuit of ultra-high heat dissipation efficiency under extreme computing power density requires addressing the ultimate heat flux density of high-performance computing chips such as GPUs/ASICs, and relies on cutting-edge solutions including high-density heat spreading and liquid cooling technologies.

02 3C Consumer Electronics

Balancing performance and heat generation in extremely thin and compact spaces relies on ultra-thin vapor chambers (VCs), graphene and other advanced materials to achieve rapid heat spreading, thus ensuring optimal user experience.

03 New Energy Vehicles

Focusing on high safety and high reliability, it is critical to ensure the temperature uniformity of battery packs and the high-power density heat dissipation of electronic control systems, which demands lightweight and highly integrated heat dissipation systems.

04 Communication base Stations

Facing the challenges of harsh outdoor environments and continuous high-power operation, heat dissipation solutions are required to feature high reliability, corrosion resistance and strong sustained heat dissipation capacity.

Heat dissipation technology has become a key common foundational technology for breaking through performance bottlenecks in various fields and ensuring the stable operation of systems, driving continuous innovation in materials and system-level solutions. This has directly spurred the evolution of heat dissipation design towards the direction of ultra-high efficiency, precision and complexity, and integration, thus posing revolutionary requirements for manufacturing technologies.

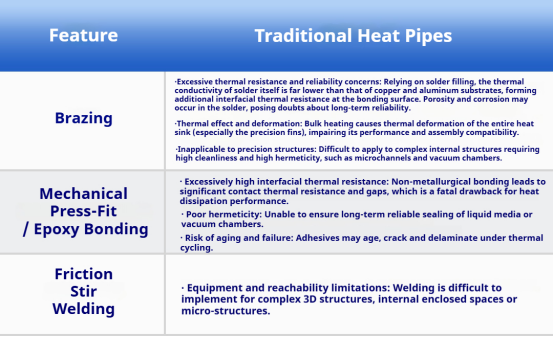

Traditional Manufacturing Technologies

Traditional manufacturing technologies for heat sinks mainly adopt such joining technologies as brazing, mechanical lamination/epoxy bonding and friction stir welding. However, these conventional methods are unable to meet the requirements of next-generation heat sinks in terms of interfacial thermal resistance, structural accuracy, hermetic reliability and adaptability to complex geometric shapes. Laser welding processes, with their unique advantages, have gradually emerged as the mainstream joining technology for heat sinks.

New Laser Welding Process

Laser welding is a welding method characterized by high-energy beam, high precision, low thermal effect and high-strength bonding. The welding process is easily adaptable to automated integration, which significantly boosts production efficiency and product consistency. It is ideally suited for the modern, high-precision manufacturing of high-end, compact heat dissipation components, and effectively addresses the industrial difficulties and pain points in the manufacturing process and subsequent service life of such components.

Advantages of Laser Welding in the Manufacturing of Heat Dissipation Components

01 Reduce Interfacial Thermal Resistance and Enhance Product Hermeticity

The laser welding process achieves metallurgical bonding of materials, drastically reducing interfacial thermal resistance. The weld composition is close to that of the base metal, delivering high joint strength and excellent hermeticity as well as good continuity of heat conduction—this is the most critical factor for improving heat dissipation efficiency.

02 Control Product Deformation and Ensure Dimensional Stability

The welding process features controllable heat input and minimal thermal deformation, which can avoid fin collapse or overall warpage caused by conventional welding. This ensures the dimensional stability and long-term reliability of complex heat sinks (e.g., skived fin heat sinks, vapor chambers (VCs)).

03 Enable Processing of Precision Structures and Complex Geometric Shapes

It can form precise, micro-scale weld seams (down to the micron level), causing almost no damage to surrounding precision fins or internal microchannel structures. As a non-contact processing method, it can be flexibly guided via optical systems to easily achieve welding along complex 2D and 3D trajectories, effectively preserving the original performance and surface integrity of heat sinks.

04 Wide Range of Weldable Materials

It enables high-strength bonding of both homogeneous and dissimilar materials (e.g., copper-steel, copper-aluminum, etc.), and is capable of welding highly thermally conductive and highly reflective copper, aluminum and their alloys. This effectively achieves material lightweighting and performance optimization, providing greater design freedom for heat sink development.

Application of Laser Technology in Heat Sink Welding

In the field of heat dissipation technology, the products with the highest technological content are undoubtedly vapor chambers and cutting-edge loop heat pipes (LHPs), which represent the technological pinnacle of current passive heat dissipation solutions. Vapor chambers have become a key component for solving the thermal bottleneck of smart phones and high-performance graphics card chips. Vapor chambers (VCs) feature extremely high technical barriers, which are mainly reflected in three aspects:

1. Precision Internal Structure

Its core is an internal micron-scale wick structure (e.g., sintered copper powder). The uniformity, porosity and strength of this structure directly determine the heat transfer limit and reliability of the vapor chamber, and its design and manufacturing processes are the top trade secrets of the industry.

2. Extreme Process Challenges

It is necessary to achieve high-vacuum hermetic sealing in an ultra-thin cavity (now achievable at less than 0.3 mm) and inject a precisely metered working fluid. Ensuring cavity flatness over a large area, absolute welding reliability, and no leakage during long-term operation involves extremely complex material and process control.

3. Complex Thermophysical Design

It is essential to precisely balance capillary force, fluid flow and phase change efficiency to cope with the extremely high local heat flux density of chips up to several hundred W/cm², and the design has an extremely low tolerance for error.

Core Principle of Vapor Chamber (VC):

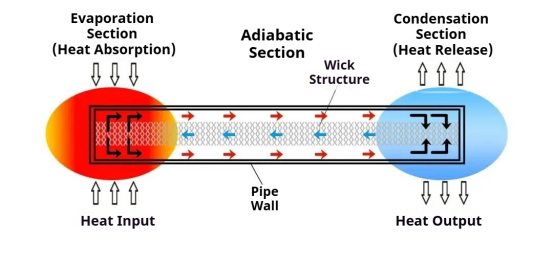

It efficiently transfers heat by utilizing the phase change cycle of liquid evaporation for heat absorption and vapor condensation for heat release. The working process is divided into four steps, forming a closed loop:

01 Heat Absorption and Evaporation

When a heat source (e.g., a CPU chip) comes into contact with the bottom of the VC, heat is rapidly conducted to its interior. The low-boiling-point working fluid (e.g., pure water) in the chamber’s vacuum environment instantly absorbs a large amount of heat, boils on the surface of the wick structure (sintered copper), and vaporizes from liquid to vapor.

02 Vapor Diffusion

In the vacuum environment inside the chamber, the vapor spreads rapidly to the entire cavity (low-temperature, low-pressure areas), enabling the heat from a point or linear heat source to be evenly diffused across the entire VC planar surface in an instant.

03 Condensation and Heat Release

When the vapor reaches the cooler condensation zone (usually connected to heat dissipation fins), it releases the latent heat of vaporization it carries and condenses back into liquid. Heat is transferred from the VC shell to the fins and ultimately dissipated by the fan airflow.

04 Liquid Reflux

Driven by the capillary force generated by the porous wick structure, the condensed liquid is automatically sucked back from the condensation zone to the evaporation zone, completing the cycle without any mechanical pump.

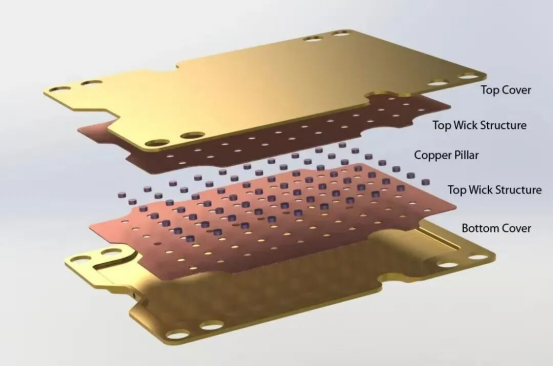

A vapor chamber is typically made of copper, stainless steel, composite materials or titanium alloy, consisting of upper and lower cover plates with a special internal wick structure sintered from copper mesh, stainless steel mesh or titanium mesh. It is essentially a flattened version of a heat pipe. The welding processes involved in its manufacturing include laser spot welding of the mesh, lamination of upper and lower covers, edge sealing of upper and lower covers, fluid injection and sealing, as well as welding of peripheral structural components.

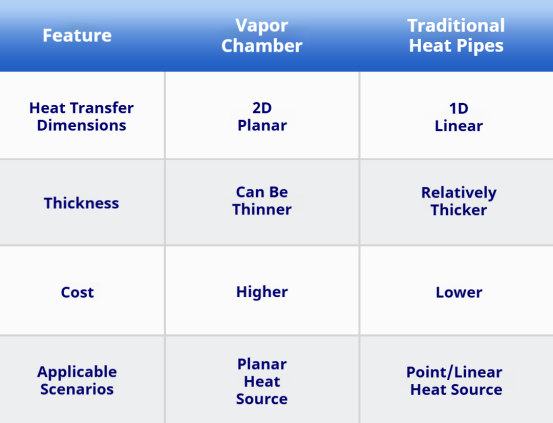

The thermal conductivity of a traditional heat pipe is approximately 5000–10000 W/m·K, while that of a VC ranges from 10000–20000 W/m·K—twice or even higher than the heat dissipation efficiency of a heat pipe. A heat pipe can be regarded as conducting heat via 1D point-to-point transfer, whereas a VC achieves 2D surface-to-surface heat dissipation, resulting in a larger heat dissipation area and higher heat removal capacity per unit time. Most importantly, it can accommodate the heat dissipation of multiple heat sources at different heights.

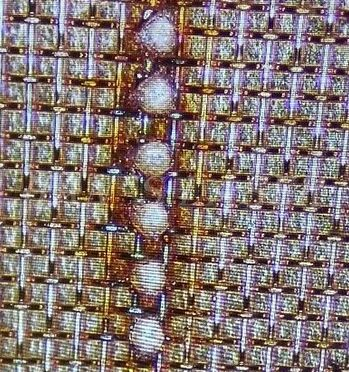

01 Vapor Chamber (VC) – Laser Spot Welding for Mesh

Laser spot welding for mesh is a key process step in VC heat dissipation technology, mainly used to weld and fix wick structures such as copper mesh to heat sink substrates, forming a complete heat dissipation channel. This process demands high precision and high reliability, requiring uniform and firm weld spots without compromising heat dissipation performance. During welding, it is necessary to address issues such as thin copper material and easy deformation, and ensure welding strength and hermeticity to meet the stable operation requirements of VC heat sinks in high-temperature and high-load environments. This process is one of the core links for improving VC heat dissipation efficiency and product quality.

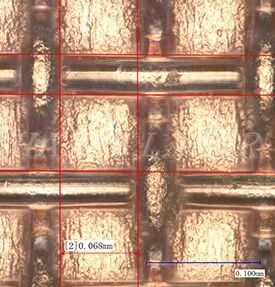

For laser spot welding for mesh, the Mobile Component and Heat Sink Welding Project Center of Han’s Laser adopts a new type of precision laser micro-welding equipment. By precisely controlling the welding heat input (at millijoule level), the equipment achieves reliable localized fusion bonding between copper mesh and substrates. Meanwhile, it ensures no penetration or leakage of ultra-thin VC sheets and almost no welding back marks. This is currently the only solution in the industry capable of stable control of welding depth at the micron (μm) level.

Case Sharing

Welding Materials: 0.055mm copper mesh + 0.06mm copper sheetProcess Requirements: Achieve bonding between copper mesh and copper sheet; reduce wire breakage during welding; ensure no penetration on the back side, as well as guaranteed welding strength and no delamination.Welding Challenges: Ensure no delamination or cold welding of copper mesh; achieve micron-level processing and precise heat input; control welding penetration depth ≤30μm.

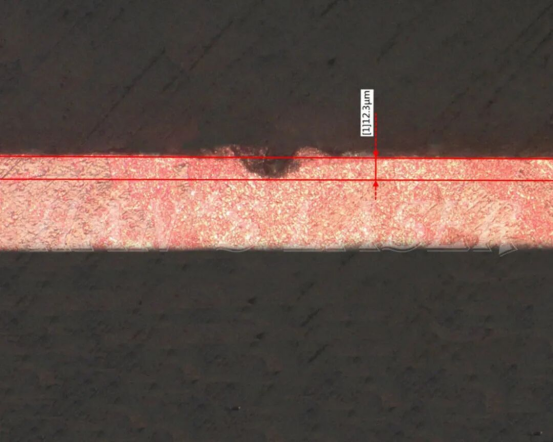

1. VC Mesh Spot Welding Effect

2. Copper Mesh Specification

3. Weld Spot Morphology A

4. Weld Morphology B

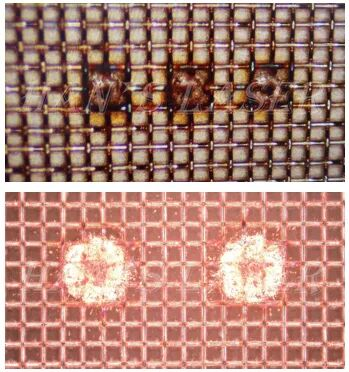

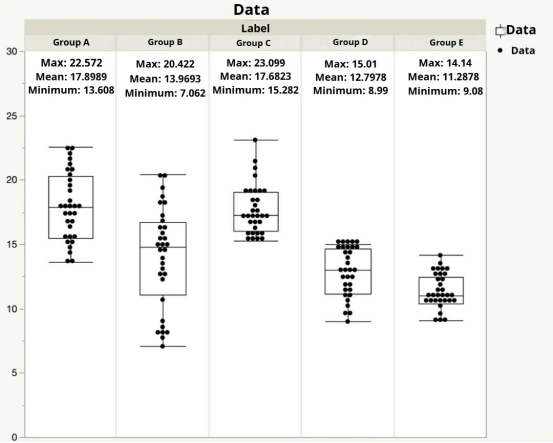

For the quantitative depth detection of micro weld spots, 32 pieces of materials were scanned for each parameter set. Regardless of whether the weld spots are located at the copper mesh openings or on the mesh wires, the depth values are all within 25 μm. No excessive depth or copper sheet penetration was observed in the metallographic sections.

5. Weld Spot Depth Data

6.metallographic Sections

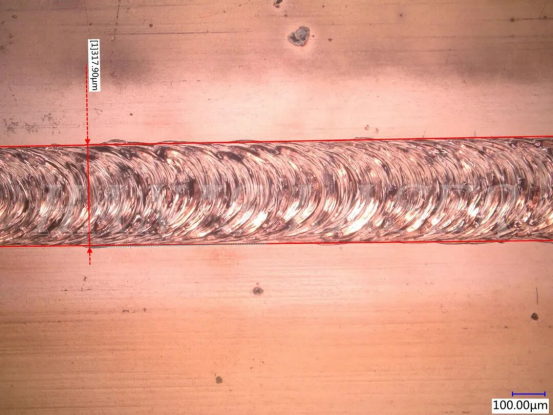

02 Vapor Chamber (VC) – Laser Welding for Pre-fixation

The laser welding process for VC pre-fixation achieves fixed bonding of the upper and lower cover plates by focusing laser beam energy to weld the VC's top and bottom plates at pre-fixed positions. Laser welding features advantages such as high precision, a small heat-affected zone (HAZ) and high welding strength. This pre-fixation process improves production efficiency and assembly precision, making it suitable for manufacturing ultra-thin VCs with complex structures. It is widely used in fields with high heat dissipation requirements such as electronic devices and data centers.

Case Sharing

Welding Materials: 0.1mm upper cover copper sheet + 0.15mm lower cover copper sheetProcess Requirements: Ensure a certain structural strength; no cold welding or penetration at weld spots; the material exhibits a tearing effect after destructive testing.Welding Challenges: Maintain a stable welding process; conduct galvanometer welding over a large area; precisely control welding heat input; ensure consistent weld penetration.

1. Weld Spot Appearance

2. metallographic Sections

03 Vapor Chamber (VC) – Laser Welding for Edge Sealing

Laser welding for VC edge sealing is the core process to ensure the cavity hermeticity. It adopts a high-energy laser beam to precisely fuse the edges of the upper and lower cover plates, forming a hermetic welded structure. By focusing on micron-scale weld seams, this technology significantly reduces thermal deformation, ensures flatness and structural strength, and effectively mitigates the pollution and energy consumption issues associated with conventional brazing.

Case Sharing

Welding Materials: 0.15mm upper cover copper sheet + 0.2mm lower cover copper sheetProcess Requirements: Achieve hermetic seam welding of the upper and lower copper alloy VC covers, control welding deformation, and ensure a certain level of welding strength.

Welding Challenges: Maintain a stable welding process and consistent weld penetration; ensure consistent welding speed for complex welding trajectories; precisely control the welding heat input.

1.Welded Products

2.Weld Seam Appearance

3. metallographic Sections

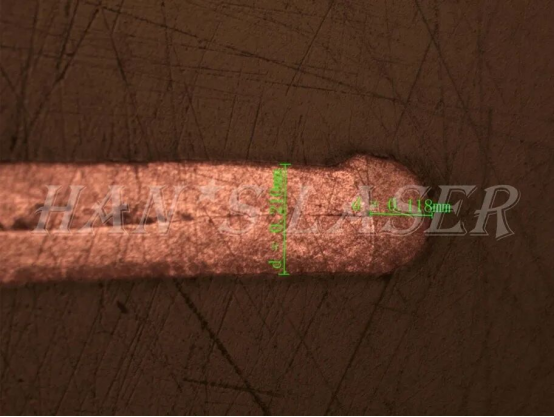

04 Vapor Chamber (VC) – Laser Welding for Sealing Port

Laser welding for the VC sealing port involves focusing a high-energy-density laser beam on the liquid filling port of the vapor chamber, causing the metal material to instantly melt and fuse, and form a hermetic weld seam. This process boasts advantages such as high precision, a small heat-affected zone and excellent hermeticity. It can ensure the internal vacuum environment of the VC and the sealing of the working fluid, prevent leakage, and thus guarantee heat dissipation performance. Laser welding enables micron-level precision control, adapting to the welding requirements of ultra-thin VCs (e.g., with a thickness of 0.2–0.3 mm). It also reduces thermal deformation and improves product reliability, making it one of the core technologies in modern VC production.

Case Sharing

Welding Material: 0.1mm Cu + 0.1mm Cu, end hermetic welding

Welding Requirements: Maintain a stable welding process with no spatter bursts or cold welding; ensure the product is hermetically sealed and can withstand a certain barometric pressure.

1. Welded Products

2. Weld Seam Appearance

3. Product metallography

05 Vapor Chamber (VC) – Laser Welding of VC and Structural Components

Laser welding of VC and structural components is a precision welding process, mainly used to ensure tight bonding between the VC and the heat-dissipated structural components. This process features the following advantages:

High Precision: The laser beam achieves concentrated energy focus, enabling micron-level weld seam control to ensure welding accuracy and avoid issues such as cold welding and skip welding.

Minimal Thermal Effect: The localized heating characteristic reduces thermal deformation of surrounding materials, making it particularly suitable for welding ultra-thin VCs (e.g., with a thickness of 0.2–0.3 mm). It prevents leakage of the internal working fluid and ensures heat dissipation performance.

Automation Compatibility: The process can be integrated with automated production lines to improve production efficiency and product consistency, meeting the requirements of mass production.

This process is a key link in the VC heat dissipation system and is crucial for enhancing the heat dissipation performance and reliability of electronic devices.

Case Sharing

Welding Material: Welding of 0.05–0.25mm Cu/SUS/Composite Materials with 0.3–0.6mm AL/SUS/Composite Materials

Welding Requirements: Maintain a stable welding process and excellent appearance; meet certain strength requirements; no spatter bursts or cold welding.

1. Laser Welding of VC and Middle Plate

2. metallographic Sections

Targeting the welding of vapor chambers (VCs), Han’s Laser has rapidly developed a new laser welding process. This process has gained recognition and large-scale application and promotion among major domestic and overseas VC manufacturers, establishing Han’s Laser’s leading position in the field of VC laser welding.

Breaking the Heat Dissipation Dilemma of Computing Power Upgrade

In AI+ scenarios, heat dissipation performance has become a core bottleneck restricting the performance upgrade of products such as electronic devices.

As the only provider in the industry that can deliver a complete set of micron-level laser welding solutions for VC heat sinks with stable depth control, the 3C Welding and Automation Division of Han’s Laser has actively explored flexible processing technologies. It has effectively overcome key technical challenges in VC laser welding including precision control, thermal deformation balance and defect prevention and control, broken through the limitations and shackles of traditional heat dissipation technologies, and met the high thermal management demands of the era with surging heat dissipation power consumption.

GBA High-Standard Summit Addresses Four AI+Laser Welding Core Propositions

GBA High-Standard Summit Addresses Four AI+Laser Welding Core Propositions Three Co-founders of a Leading Domestic LiDAR Maker Co-found a Robotics Firm

Three Co-founders of a Leading Domestic LiDAR Maker Co-found a Robotics Firm High-Efficiency Conversion Feeds R&D! Optoelectronic HOPE Model Builds a New Industrial Engine

High-Efficiency Conversion Feeds R&D! Optoelectronic HOPE Model Builds a New Industrial Engine Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright

Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Father of Shenguang Facility: Building Three Generations of National Strategic Equipment

Father of Shenguang Facility: Building Three Generations of National Strategic Equipment LASERVALL's Li Mengmeng: A Leader in Laser Solder Ball Welding, Deep in Automated Niche Sectors

LASERVALL's Li Mengmeng: A Leader in Laser Solder Ball Welding, Deep in Automated Niche Sectors Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

more>>

Scanner Optics: Galvanometer Tech Leader

more>>