Investing in Clean Air: Strategic Choices for Enterprises and the Key to Sustainability

source:ULT AG Contributed

release:Taiwan Laser Technology Application Association

keywords:

Time:2025-09-17

Source: ULT AG Contributed by: Taiwan Laser Technology Application Association 30th Aug 2025

Economic Challenges and the Necessity of Air Pollution Control

Against the backdrop of rising global economic uncertainty, enterprises are generally confronted with unprecedented challenges. The overall market's expectations for growth have become conservative, and enterprises have shown obvious hesitation and caution in investment planning. This has led enterprises to tend to postpone or completely rule out investment projects that do not directly generate revenue when considering them.

However, while facing economic challenges, enterprises cannot ignore the mandatory requirements from the legal aspect. Regulations in many countries generally stipulate that enterprises have the responsibility to ensure the health and occupational safety of their employees, which includes the management of air quality. In many manufacturing, processing, and high-risk working environments, the installation of dust collection and filtration systems has been made a legal obligation, with the aim of reducing exposure to harmful substances and ensuring the respiratory safety of employees during work.

Therefore, even under economic pressure, enterprises should not neglect investment in air pollution control technologies. Although the initial introduction of dust collection equipment may be regarded as a burden, in the long run, modern systems, through high-efficiency operation and intelligent control, can bring considerable energy-saving and cost benefits to enterprises.

The Regulatory framework for Air Pollution Control in Enterprises

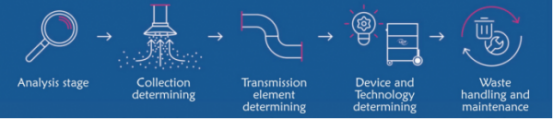

Under the legal regulations of a specific country and industry, enterprises must install and operate dust collection and filtration equipment to fulfill their obligation to protect the occupational health of their employees. These regulations are not merely suggestions but are legally binding basic requirements applicable to work environments that handle hazardous substances, generate gas particles or dust.

Figure 1: Occupational safety supervisors are measuring the concentration of pollutants in the air at a laser cutting operation site to confirm whether it complies with regulatory limits.

In certain countries, if enterprises fail to comply with the above regulations, they may not only face administrative demands and heavy fines from the competent authorities, but also bear legal liability risks. In cases of occupational diseases or major work safety incidents, they may even be subject to criminal prosecution and reputational damage. Therefore, the introduction of air pollution control equipment is no longer an "option" that enterprises can assess on their own, but a mandatory legal obligation that must be strictly implemented, directly related to the legal operation and social responsibility of enterprises.

The cost-saving benefits brought by modern dust collection and filtration technologies

The following are several major sources of cost savings centered on improving energy efficiency:

Intelligent demand-oriented control:

Modern dust collection systems are often equipped with automated control functions, such as constant negative pressure systems, which can automatically adjust air volume and power according to actual emission requirements. During periods of low emissions or non-operating hours, they automatically reduce the operating speed, effectively reducing unnecessary energy consumption.

·Thermal energy recovery design:

More and more systems are built with heat exchange modules that can use the extracted hot air to preheat fresh air. This is especially effective in winter for reducing heating costs and improving overall energy efficiency.

·Adopt EC fan motor:

Compared with traditional AC fan motors, EC fans can achieve higher energy efficiency and more precise air volume control, reduce overall energy consumption, and extend the system's lifespan.

Figure 2: Energy Efficiency Comparison Diagram of AC Fans and EC Fans @Ziehl-Abegg

·Reduction in production losses and downtime:

Dust and particles suspended in the air can accumulate on the surfaces of precision machinery, affecting their operational accuracy and even causing damage. Through an effective exhaust and filtration system, premature wear or contamination of equipment can be prevented, thereby extending the equipment's lifespan, reducing maintenance frequency, and minimizing the risk of production line disruptions caused by unexpected downtime.

·Reduction in cleaning costs:

When dust can be eliminated in real time at the source, the cleaning of production equipment and factory buildings will become simpler, and the required manpower and time will be significantly reduced. At the same time, it can also reduce the reliance on cleaning agents and consumables, effectively controlling cleaning costs.

·Improvement of Employee Health and Work Motivation:

Improving air quality can reduce respiratory diseases, allergies and other health problems related to the working environment. This not only helps to lower the rate of sick leave, but also enhances employees' concentration at work and overall morale. A healthy workforce is an indispensable source of productivity for enterprises.

·Key impacts of system design on energy efficiency:

Every component in the overall piping system (such as elbows, contraction sections, and filters) may cause pressure loss, thereby increasing the load on the fan. Through professional design and proper configuration, not only can pressure loss be reduced, but also the energy efficiency and operational stability of the entire exhaust system can be enhanced.

·Recycling and reuse of valuable substances:

In specific industries such as metal processing and chemical manufacturing, exhaust systems can assist in the recovery of valuable residues like metal powders and chemicals. This not only reduces the cost of waste disposal but also generates additional revenue.

·Positive impact on product quality:

In production lines of industries such as food, pharmaceuticals, and electronics, where environmental cleanliness is of utmost importance, airborne particles can directly affect product quality. Exhaust systems can effectively prevent contaminants from entering critical processes, improve product yield, and reduce the risk of scrapping and recalls.

Figure 3: Schematic diagram of the drainage system optimized by fluid mechanics @ULT AG

Air Pollution Control: An Inevitable Choice for Enterprises

Under the multiple pressures of the current industry and society, air pollution control is a necessary action that enterprises must face up to and implement. There are several key reasons behind this trend, making investment in dust collection and filtration technologies an indispensable part of business operations.

·Legal obligations:

As mentioned earlier, most countries have established a complete legal framework for workplace safety and environmental protection, clearly requiring enterprises to protect employees from exposure to harmful air pollutants and stipulating legally binding regulations. only by introducing appropriate air pollution control technologies can the exposure limits set by regulations be achieved to ensure that enterprises are in compliance with the law.

·Moral Responsibility:

Providing a healthy and safe working environment is not only a part of modern corporate governance but also a concrete manifestation of basic respect and care for employees. If an enterprise chooses to ignore the improvement of air quality despite knowing it is poor, it may lead to avoidable health damage. This not only causes substantial harm to employees but may also undermine the trust relationship between the enterprise and its employees in the long term, and even lead to a decline in internal morale and staff turnover.

·Long-term risk management:

From the perspective of risk management, investing in air pollution control systems is an active and forward-looking risk reduction strategy. Through such equipment, enterprises can not only effectively prevent production line disruptions or quality defects caused by equipment pollution, but also reduce multiple risks such as potential future workers' compensation claims, legal lawsuits, and damage to reputation. In the long run, it is more economically beneficial and operationally stable.

·Brand Image and Competitiveness Enhancement:

In today's society, there is an increasing focus on corporate responsibility and sustainable development. Proactively implementing air pollution prevention measures not only helps establish a positive image in the public's mind but also attracts mission-driven and professionally competent talents to join. Moreover, if a company can demonstrate its environmental protection efforts and employee care in bidding, cooperation, or customer evaluations, it will be more likely to stand out and win the trust of the market and partners.

Invest in the future and create sustainable competitiveness.

Enterprises may hesitate to introduce dust collection and filtration technologies, considering it a deferrable expense. However, a thorough analysis reveals that such investments actually offer multiple values in terms of compliance, safety, and economic benefits.

In the era of pursuing Figure 4. The LAS800Ex dust extraction device (left) is used in conjunction with the laser cleaning system, effectively controlling particle dispersion and protecting the health of operators. @cleanLASERy-saving design, low maintenance requirements, recyclable resource effects, and protection of production quality that modern dust collection systems possess not only help enterprises disperse risks in terms of law and operation, but also lay a solid foundation for future operational flexibility and sustainable goals.

Figure 4. The LAS800Ex dust extraction device (left) is used in conjunction with the laser cleaning system, effectively controlling particle dispersion and protecting the health of operators. @cleanLASER

Therefore, enterprises should make forward-looking and strategic key investments in dust collection and filtration technologies. In the constantly changing global market, those that choose to deploy ahead of time and are willing to invest in the well-being of their employees and environmental protection will have a greater chance to steadily progress in the future competitive landscape and create substantial results of continuous growth.

GBA High-Standard Summit Addresses Four AI+Laser Welding Core Propositions

GBA High-Standard Summit Addresses Four AI+Laser Welding Core Propositions Three Co-founders of a Leading Domestic LiDAR Maker Co-found a Robotics Firm

Three Co-founders of a Leading Domestic LiDAR Maker Co-found a Robotics Firm High-Efficiency Conversion Feeds R&D! Optoelectronic HOPE Model Builds a New Industrial Engine

High-Efficiency Conversion Feeds R&D! Optoelectronic HOPE Model Builds a New Industrial Engine Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright

Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Father of Shenguang Facility: Building Three Generations of National Strategic Equipment

Father of Shenguang Facility: Building Three Generations of National Strategic Equipment LASERVALL's Li Mengmeng: A Leader in Laser Solder Ball Welding, Deep in Automated Niche Sectors

LASERVALL's Li Mengmeng: A Leader in Laser Solder Ball Welding, Deep in Automated Niche Sectors Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

more>>

Scanner Optics: Galvanometer Tech Leader

more>>