The Application of Laser-Arc Hybrid Welding in the Shipbuilding Industry

source:Fabricating

keywords:

Time:2025-09-06

Source: Fabricating 4th September 2025

With the advancement and development of technology, the production technology level of ships has improved, and shipbuilding materials and ship design have also changed over time. The "Medium and Long-Term Development Plan for the Shipbuilding Industry" approved and issued by the General Office of the State Council during the 11th Five-Year Plan period clearly stated the guidance and development direction of the shipbuilding industry planning. Its policy is to deeply transform and accelerate development, unswervingly follow the new industrialization path; at the same time, enhance the ability of independent development and innovation and the supporting capacity of ship equipment, and improve the core competitiveness of China's shipbuilding industry; balance "attracting in" and "going out", and at the same time, shipbuilding companies should focus on introducing and digesting and absorbing core technologies such as modular outfitting, high-efficiency welding and cutting in shipbuilding, and develop modern shipbuilding industry production and operation management methods in China.

Development of Laser-Arc Hybrid Welding

Laser welding, as an emerging welding process, is gradually making its mark in various industries. It boasts advantages such as high welding efficiency, good weld quality, and relatively low material consumption. For medium and thick plate materials, laser-arc hybrid welding has become the leading welding technology and is currently being applied in industries such as aerospace, military, rail transportation, steel structures, and shipbuilding.

For the butt welding of ship plates in the planar sections during the shipbuilding process, Penta Laser has developed high-power laser-arc hybrid welding technology, including trolley-type laser-arc hybrid welding machines suitable for ship butt welding and large gantry laser-arc hybrid welding machines. The robot laser-arc hybrid welding machine is shown in Figure 1.

Figure 1 Robot Laser-Arc Hybrid Welding Machine

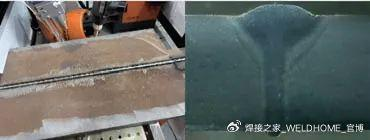

In traditional ship plate welding, submerged arc welding or gas shielded welding is generally adopted. Traditional submerged arc welding cannot achieve double-sided formation with single-sided welding. After the front side welding is completed, a flipping process is required to perform the back side welding again. The area of the welded ship is large and the plate thickness is large, so the flipping requires special equipment, which is expensive and has certain risks during use. To avoid the risks in the production and manufacturing of ship planar sections, foreign shipbuilding companies, especially some European ones, have successively introduced laser-arc hybrid welding technology and equipment. The weld morphology of laser-arc hybrid welding is shown in Figure 2.

Figure 2 Morphology of the weld seam in laser-arc hybrid welding

Cart-type laser-arc hybrid welding machine

The trolley-type laser-arc hybrid welding machine (Figure 3) is designed for the ship plate splicing and welding station in the planar section. The overall structure of this equipment is similar to that of the ship submerged arc welding trolley, featuring three servo axes, namely X, Y, and Z axes. Additionally, the equipment is equipped with a weld seam tracking system, which can monitor the weld seam in real time and ensure the accuracy of the weld seam position. In terms of process, the laser-arc hybrid welding process is adopted, enabling single-sided welding with double-sided formation. Regarding laser power, it can be paired with a 20-30kW laser to achieve flip-free welding for 6-30mm thick plates. Compared with traditional welding, the welding material consumption is reduced by 80%, and the power consumption is reduced by 40%.

Figure 3 Trolley-type Laser-Arc Hybrid Welding Machine

Large gantry laser-arc hybrid welding machine

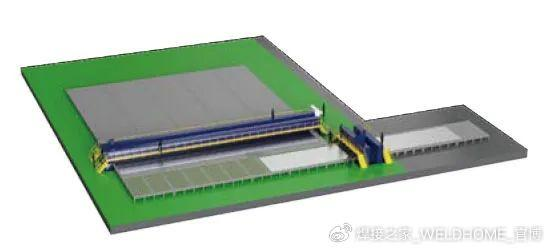

The large gantry laser-arc hybrid welding machine (Figure 4) is an equipment designed for the automated assembly line of flat segmented ship plates. Unlike the trolley-type laser-arc hybrid welding machine, the gantry-type hybrid welding machine adopts a working principle where the gantry is fixed and the ship plates move on the worktable. Similarly, the gantry-type hybrid welding machine is equipped with three servo axes and a weld seam tracking system. In terms of process, it adopts the laser-arc hybrid welding process, which can achieve single-sided welding with double-sided formation. In terms of laser power, it can be matched with a 20-30kW laser to achieve flip-free welding of 6-30mm thick plates. Compared with traditional welding, the welding material consumption is reduced by 80% and the power consumption is reduced by 40%.

Figure 4 Large gantry laser-arc hybrid welding machine

Specialized machine for H-beam laser-arc hybrid welding

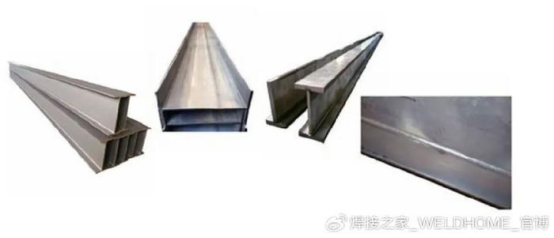

The H-beam laser-arc hybrid welding dedicated machine (Figure 5) adopts the laser-arc hybrid welding process and is suitable for the welding of T/H-beams. The welding effect is shown in Figure 6. The equipment features: high-efficiency welding with a welding speed up to 1.8m/min; laser deep penetration welding, achieving full penetration of the web; low welding material consumption, 1/5 of traditional welding; customizable processing size; capable of group assembly welding, correction in one process; fully automatic control, one-button start, and convenient operation.

Figure 5 Special machine for laser-arc hybrid welding of H-shaped steel

Figure 6 Welding Sample Display

Closing Remarks

In summary, in the planar sections of shipbuilding, PENTRonIC has developed two types of equipment for ship plate splicing and welding. PENTRonIC is a foreign-controlled company. Through the globalization of its technology and the localization of its equipment, it has achieved business localization. The increasingly fierce technological progress has led to an increase in the demand for safety, reliability, and efficiency in intelligent ship production technology, shipbuilding materials, and techniques. The traditional cutting and welding technologies in the shipbuilding industry will surely be replaced by new technologies. Laser is also known as "the fastest knife", "the most accurate ruler", and "the brightest light". With its advantages of precise beam and high speed, laser manufacturing technology is bound to play a pivotal role in the intelligent ship production process, whether in planar cutting or welding.

GBA High-Standard Summit Addresses Four AI+Laser Welding Core Propositions

GBA High-Standard Summit Addresses Four AI+Laser Welding Core Propositions Three Co-founders of a Leading Domestic LiDAR Maker Co-found a Robotics Firm

Three Co-founders of a Leading Domestic LiDAR Maker Co-found a Robotics Firm High-Efficiency Conversion Feeds R&D! Optoelectronic HOPE Model Builds a New Industrial Engine

High-Efficiency Conversion Feeds R&D! Optoelectronic HOPE Model Builds a New Industrial Engine Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright

Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Father of Shenguang Facility: Building Three Generations of National Strategic Equipment

Father of Shenguang Facility: Building Three Generations of National Strategic Equipment LASERVALL's Li Mengmeng: A Leader in Laser Solder Ball Welding, Deep in Automated Niche Sectors

LASERVALL's Li Mengmeng: A Leader in Laser Solder Ball Welding, Deep in Automated Niche Sectors Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

more>>

Scanner Optics: Galvanometer Tech Leader

more>>