"Flexible Screen" - a new "battlefield" for laser processing technology applicat

source:Laserfair

release:Nick

keywords: Flexible Screen laser processing

Time:2019-03-01

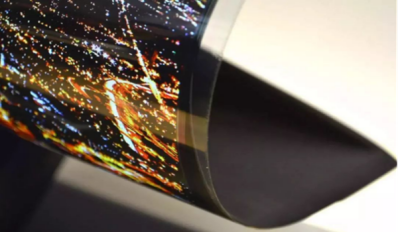

"Flexible Screen" - a new "battlefield" for laser processing technology applications

With the advent of the full-screen mobile phone era, major mobile phone brands have begun to focus on the next generation of display - flexible screen. Not long ago, Samsung has been the initiator of flexible screens, and has also exposed a number of foldable mobile phones, but since this year, Chinese manufacturers have successively released foldable products based on flexible screens, including Huawei and Lenovo.

In order to manufacture ultra-thin, beautiful, high-tech flexible display products, each process in the production process of materials, devices, circuit design, and finished products must ensure the quality and yield of the products to the utmost. With the continuous maturity of laser technology, the realization of high-precision flexible material processing is no longer a problem.

As an emerging flexible display technology, OLED is increasingly used in smartphones. Compared with the processing of brittle materials of conventional LCDs, OLEDs have very high precision requirements in the manufacturing process due to their complicated layered structure.

OLED uses self-illumination technology, the thickness is less than 1 mm, and it is lighter and thinner than the traditional LCD display structure. This also constitutes the two-layer glass base layer of the OLED support structure and the glass thickness is required to be ultra-thin. At the same time, one of the key issues of OLED technology is that it is susceptible to environmental influences. It must be packaged with the highest precision to isolate oxygen and water vapor, which puts higher requirements on the precision of glass sealing. Cutting glass with conventional machining methods is prone to problems such as chipping and cracking. In contrast, the laser cutting process uses non-contact processing for thin glass and ultra-thin glass processing. It has the advantages of cutting by special shape, small cutting edge and high precision, and greatly improves the workpiece yield and processing efficiency.

With the trend of OLED flexible display technology, more and more laser companies are beginning to lay out new strategies: Coherent has introduced a new generation of ultrashort pulse laser HyperRapid NX with high pulse repetition frequency. It delivers 30W of average UV power at repetition rates up to 1,600 kHz, making it the benchmark for OLED cutting applications. The first flexible OLED laser cutting equipment independently developed by Han’s Display and Semiconductor was officially put into operation in June this year. This equipment integrates slitting, chamfering and inspection. It is mainly used for laser cutting of OLED polymer materials, which promotes the rapid development of flexible display technology. HG Laser has developed an OLED panel glass profiled automatic cutting machine with a picosecond laser. Developed for rapid cutting of OLED panels and integrated with automated optical inspection/ultrasonic splitting for batch production.

Since the development of the mobile phone industry, flexible screen +5G has become a new battlefield for mobile phone manufacturers. In response to the new demands and new challenges that come with it, I believe that many laser equipment companies are ready to go.

GBA High-Standard Summit Addresses Four AI+Laser Welding Core Propositions

GBA High-Standard Summit Addresses Four AI+Laser Welding Core Propositions Three Co-founders of a Leading Domestic LiDAR Maker Co-found a Robotics Firm

Three Co-founders of a Leading Domestic LiDAR Maker Co-found a Robotics Firm High-Efficiency Conversion Feeds R&D! Optoelectronic HOPE Model Builds a New Industrial Engine

High-Efficiency Conversion Feeds R&D! Optoelectronic HOPE Model Builds a New Industrial Engine Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright

Four-Meeting Linkage: China Laser CEO Shenzhen Night Shines Bright Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Father of Shenguang Facility: Building Three Generations of National Strategic Equipment

Father of Shenguang Facility: Building Three Generations of National Strategic Equipment LASERVALL's Li Mengmeng: A Leader in Laser Solder Ball Welding, Deep in Automated Niche Sectors

LASERVALL's Li Mengmeng: A Leader in Laser Solder Ball Welding, Deep in Automated Niche Sectors Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

more>>

Scanner Optics: Galvanometer Tech Leader

more>>