Additive manufacturing makes headway in aircraft production

source:

keywords: Additive manufacturing

Time:2017-10-21

Airbus' investigations into additive manufacturing processes started more than 20 years ago, first with plastics and rapid prototyping applications and a few years later on laser beam melting (LBM) and electron beam melting (EBM) for metal applications. A problem that still somewhat exists for the company is coming to additive manufacturing solutions with a solid business case, and how to start if nearly every industrial decision is driven by business-case discussions.

Ninety-five percent of the time, additive manufacturing makes it easier, cheaper, and faster to jump into a project, rather than trying to get permanently improving basic figures through deep investigations for future decisions.

Fast-track product developments

One example of additive manufacturing capabilities is the machines themselves. In 2012, the company started with one 250W (250 × 250 × 280mm) LBM machine, and now has two to four 400W/1kW lasers (up 800 × 400 × 500mm) in service—a trend that will continue to be boosted by completely new types of multilaser systems in the next 10 years.

Business cases will also be feasible for low-cost products mid-term (2020 onwards) for the company. The key lesson learned after seven years, with more than 250 metal additive manufacturing projects so far, is that additive manufacturing will enable highly integrated and multifunctional products, with big opportunities in the future in terms of ecological and environmental footprint.

Materials, processes, and machines

Materials. Because of future business cases, Airbus first focused on titanium (Ti6-4), followed by Inox, and is planning on aluminum applications by the end of 2018. LBM/EBM-based additive manufacturing on Ti6-4 has been on Technology-Readyness-Level (TRL) 6 since the end of 2015, and the first low-rate serial parts were delivered by Premium Aerotech (a subsidiary of Airbus) at the end of 2015.

One additional opportunity will be available for serial applications in 2018 onwards with Scalmalloy, a high-performance aluminum alloy managed by the Airbus subsidiary AP-Works. From 2018 onwards, the company will have a first set of additive manufacturing materials available to start real serial production. One of the biggest challenges for future additive manufacturing serial applications is the availability of low-cost metal powders, so it is good to see all activities all over the world following that future need.

Processes. Fused deposition modeling (FDM; using Stratasys Fortus machines) has been in serial mode for two years now on Airbus A350 parts. Selective laser sintering (SLS) with polyamide (PA) has been used on demonstrator parts and first serial applications on helicopters and brackets for the company's new Beluga transport aircraft. Because of limited fire resistance capability, this has not yet been applied on passenger aircraft up to now.

Machines. The number of additive manufacturing machine suppliers is increasing rapidly, which leads to competition in the worldwide market. From an industrial view, in-process quality tools play a key role for future automated additive manufacturing facilities. In 10 years, we will see a bundle of different machine sizes and part-specific additive manufacturing machines, as well as multifunctional additive manufacturing systems. For example, an additive manufacturing machine supplier in The Netherlands offers a machine with integrated heat treatment, and the DMG Mori milling center integrates an HDR powder-feed additive manufacturing tool.

First steps aboard flying aircrafts

In February 2014, Airbus delivered the first printed FDM spare part to an airline after a two-year project with a 3D redesign of a 30-year-old manual drawing of a cabin-attendant seat part. It's now a pure digital product, produced more or less on demand by Airbus itself instead of a 10-year inventory because of the press forming production with a 20-year-old "serial tool."

The first few-hundred flight test bracket FDM applications had been aboard the new A350 test aircraft beginning in 2014, and the first additively manufactured titanium Bionic cabin bracket produced using the LBM process and a new topology-optimized design method was flown on an A350 in June 2014 after two years of testing (FIGURE 1). All these activities have been extremely useful for the future of additive manufacturing at Airbus, as they have demonstrated technical feasibility and future opportunities for real industrial usage of additive manufacturing from 2016 onwards.

FIGURE 1. The Bionic cabin bracket was produced from titanium using laser beam melting (LBM).

There are demonstrated additive manufacturing capabilities in flight safety-relevant hydraulic components. Up until now, mostly LBM projects have been produced—95% of which were manufactured by Airbus partners Laser Centre North (LZN), Hofmann Innovation Group, Toolcraft, and AP-Works, among others.

Application examples

High-speed development process. The Testing High-tech Objectives in Reality (THOR) aircraft, a 3.7m flyable platform almost completely printed out of plastics and a few aluminum parts, has an in-flight weight less than 25kg. The target was to demonstrate additive manufacturing capabilities in competition with theoretical investigations. FIGURE 2 shows a successfully demonstrated THOR aircraft in service.

FIGURE 2. A Testing High-tech Objectives in Reality (THOR) aircraft, produced entirely using additive manufacturing, is shown in flight.

Flight test LBM hardware.Titanium, Inox, and aluminum parts were tested in service on several A350/A330NEO test aircrafts, including an aluminum camera cover for a vertical tail plane (FIGURE 3).

FIGURE 3. An aluminum camera cover for a vertical tail plane was produced using LBM.

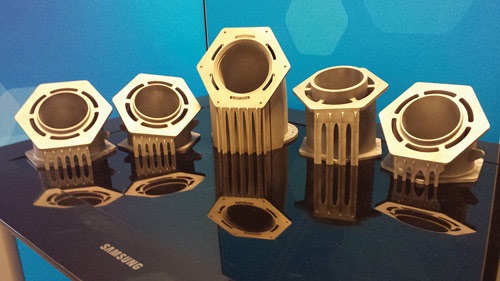

First serial titanium use on aircraft systems. First delivered in 2016, a Premium AEROTEC (PAG) titanium double-walled fuel connector that replaces a welded cast part assembly had a cost reduction of around 50% because no casting tools were needed and lead time was reduced from months down to 11 weeks (FIGURE 4).

FIGURE 4. This titanium double-walled fuel connector that replaces a welded cast part assembly had a cost reduction of around 50% because no casting tools were needed.

First serial topology-optimized titanium brackets. First serial PAG additively manufactured parts for the A350 aircraft with a weight reduction of 30% will be delivered in the fourth quarter of 2017.

Flight safety-relevant additively manufactured hydraulic component. On March 30, 2017, the first flight of a flight safety-relevant additively manufactured component on an A380 aircraft enabled 35% weight reduction (FIGURE 5).

FIGURE 5. This flight safety-relevant additively manufactured component enabled 35% weight reduction on an A380 aircraft.

From first parts to clean sheet designs

The first step into a new area of additive manufacturing is a 1:1 exchangeable additively manufactured part, while the next step is to rethink the complete component.

The goal is to make full use of the free room for multifunctional and highly integrated "clean-sheet-designs" enabled by additive manufacturing. This could be a hydraulic unit or bracket with a three-part assembly that had previously been made from 126 parts and rivets. This means no costs for the roughly 120 parts, which leads to 95% less assembly (and no tooling maintenance, stock, and logistics). Such cases are under investigation for serial use in 2019 onwards.

Additive manufacturing allows us to really rethink a product, such as copying a giant water lily structure into a spoiler or transferring the growth of a slim mold into design mathematics, as demonstrated by a Bionic-Partition project with 3D design software company Autodesk and other partners. The project demonstrates capabilities of generic design methods linked with future additive manufacturing production, leading to a 45% weight reduction and therefore saving around -3 tons of fuel/year for an A320 aircraft (FIGURE 6).

FIGURE 6. The Bionic-Partition project demonstrates capabilities of generic design methods linked with future additive manufacturing production, saving around -3 tons of fuel per year for an A320 aircraft.

Outlook for 2025

In 2016, we started to develop a view on 2025 with the help of 10 universities and institutes, looking at fast-track product development, eliminating the need for tooling, production on demand, decreased raw material needs, step change in weight reduction, and more enabled by additive manufacturing.

Complete industrialization must be organized and developed for the additive manufacturing market to continue to grow. The biggest challenges are to understand "clean-sheet-design" future product opportunities, and to develop all necessary design principles and industrial software solutions. Then, all of this must be validated, including new requirements and acceptance from authorities.

MOST READ

- RoboSense is to Produce the First Chinese Multi-beam LiDAR

- China is to Accelerate the Development of Laser Hardening Application

- Han’s Laser Buys Canadian Fiber Specialist CorActive

- SPI Lasers continues it expansion in China, appointing a dedicated Sales Director

- Laser Coating Removal Robot for Aircraft

PRODUCTS

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays

New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays A new industrial compression module by Amplitude

A new industrial compression module by Amplitude Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of

Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>

Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>