Chinese firm develops country's first semiconductor laser invisible wafer scribing machine

source:

keywords:

Time:2020-10-07

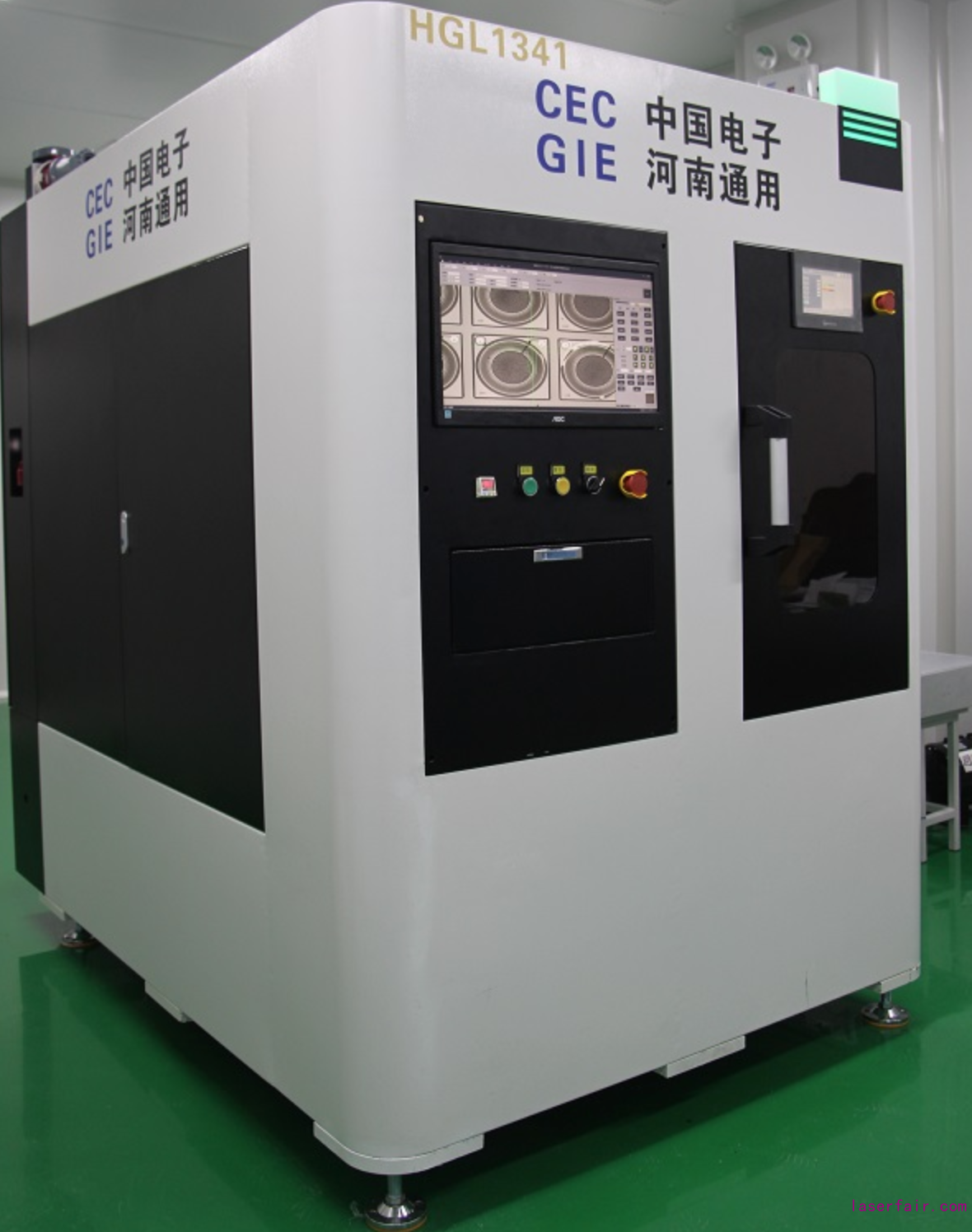

A Chinese company has developed the country's first semiconductor laser stealth wafer scribing machine after one year's work.

The equipment is jointly developed by China Great Wall Computer, a subsidiary of China Electronics Corporation, Zhengzhou Institute of Railway Information Technology and Henan General Intelligent Equipment Co.

The device is at the international leading level in key performance parameters, marking a substantial and significant breakthrough in China's semiconductor laser stealth wafer cutting technology, a milestone in further improving China's intelligent equipment manufacturing capabilities.

Laser cutting is a non-contact process that avoids damage to the surface of the crystalline silicon compared to traditional cutting methods.

Laser cutting is characterized by high processing accuracy and high processing efficiency, which can greatly improve the quality, efficiency and effectiveness of chip production and manufacturing.

By using special materials, special structure design and special motion platform, the semiconductor laser invisible wafer cutting machine can achieve high stability and high precision when the processing platform moves at high speed, and the motion speed can reach 500mm/s, which is much more efficient than foreign equipment.

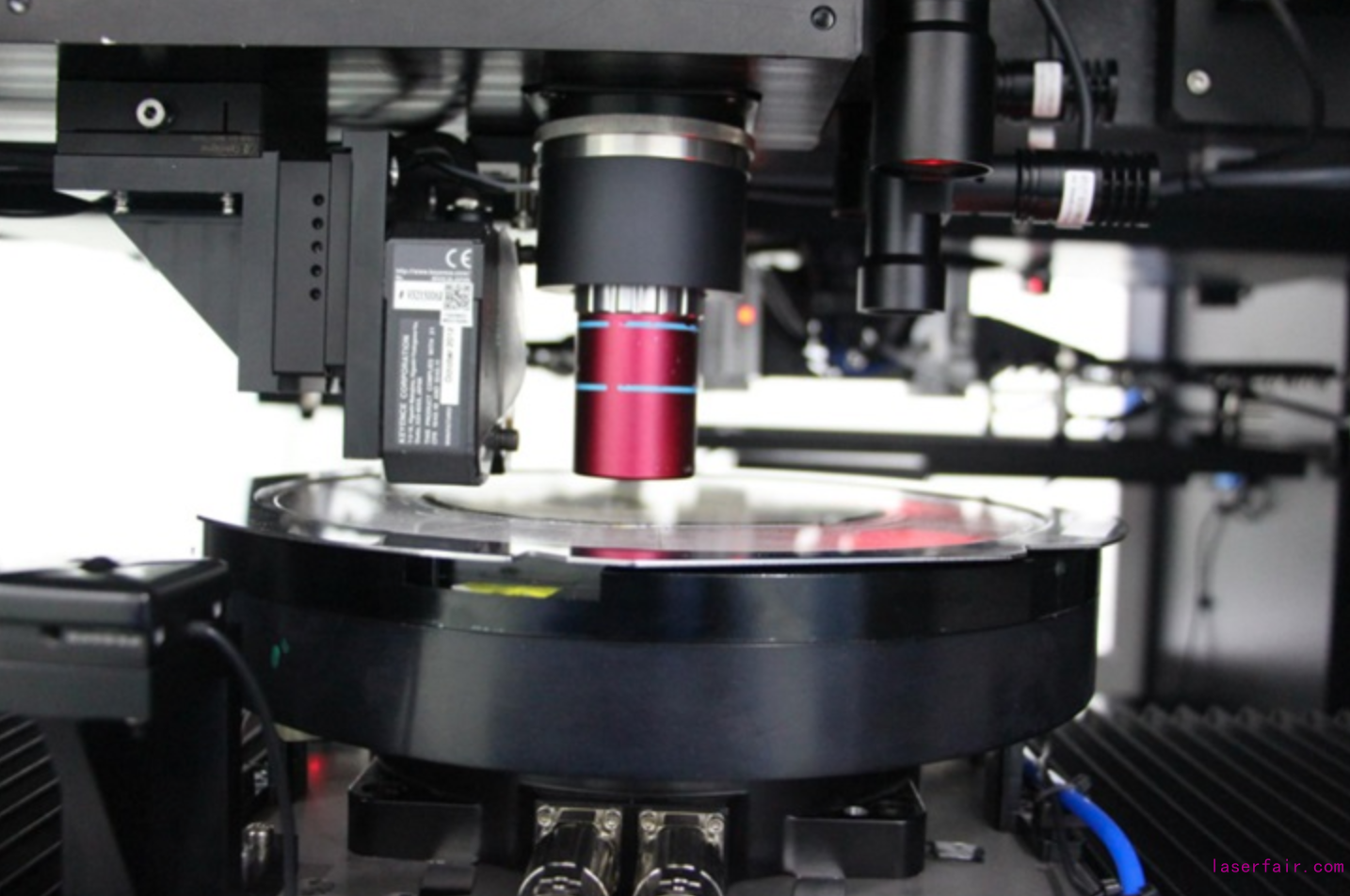

On the optical side, based on the spectral characteristics of monocrystalline silicon, combined with the application level of industrial lasers, a laser with the appropriate wavelength, total power, pulse width and heavy frequency was used to achieve the final invisible cutting.

In terms of imaging, it uses cameras with different pixel sizes and different sensor chips with lenses of different efficacy to achieve product profile recognition and low, medium and high magnification level adjustment.

It is also equipped with a coaxial imaging system, which ensures real-time confirmation and optimization of the effect during cutting for optimal cutting results.

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit

Lead the Intelligent Welding Revolution: Greater Bay Area AI + Laser Welding Summit Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track

Splashing 200 Million Yuan! Three Industry Giants Boost Investment in the Laser Track Two New Companies Established! Han's Ecosystem Further Expands

Two New Companies Established! Han's Ecosystem Further Expands Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly

Multi-Sector Flourish! Five Major Laser Parks Rise Rapidly The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

The Grand Finale is Here! Three Major Laser Headquarters Base Projects Topped Out

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception

Intelligent Scientific Systems: Leading Domestic Ultrafast Imaging, Redefining Visual Perception From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey

From Rural Girl to Laser Helmsman: Fu Chunhua's Light-Chasing Journey Scanner Optics: Galvanometer Tech Leader

Scanner Optics: Galvanometer Tech Leader The "Light Chasers" in the Deep Ultraviolet World

The "Light Chasers" in the Deep Ultraviolet World Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

more>>